62

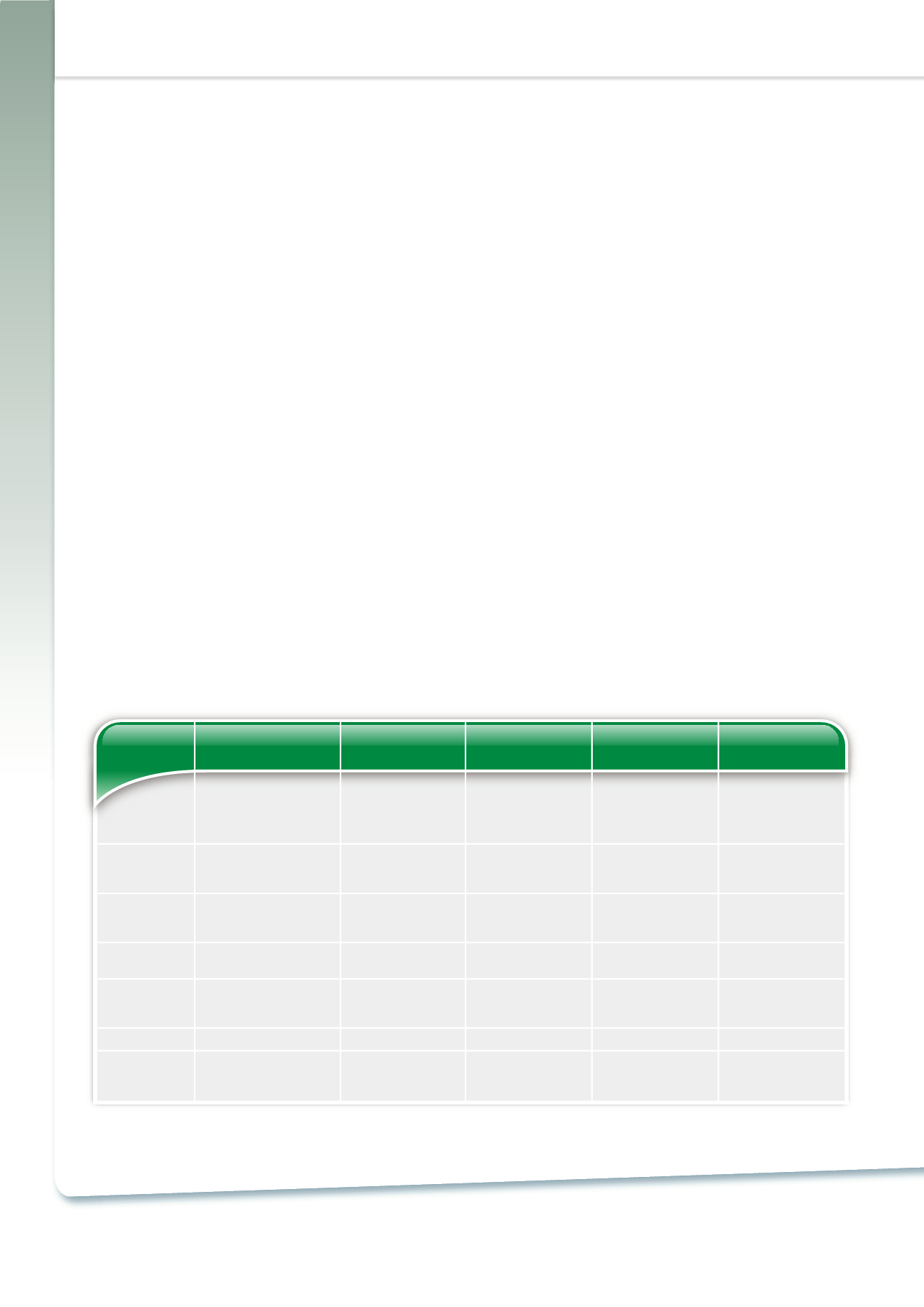

Viruses Used in Virus Validation Studies

Viruses that potentially may contaminate plasma, i.e., HIV,

WNV, HAV, and B19V, or their model viruses, BVDV and

CPV as specific model viruses for HCV and B19V, respec-

tively, and the herpes virus

Pseudorabies virus

(PRV), an

enveloped DNA virus as HBV, are chosen for virus validati-

on studies. Thus, assurance is provided that a wide range

of viruses with different physicochemical properties, that

could possibly be present in plasma, would be inactivated

and removed during the manufacturing process.

Methodology of Virus Reduction Validation

Major steps in the manufacturing process for Berinert

®

were validated in a virology laboratory. The starting materi-

al was obtained directly from the manufacturing plant and

was “spiked” with a known quantity of test virus, and the

virus inactivation/removal capacity of that step was measu-

red. The virus reduction factors for each step were then ad-

ded to result in the overall reduction factor for the process.

Results of virus validation studies are reported as x log

10

reductions. The value x is calculated by comparing the

virus load in the starting material to the virus load in

the material after the virus inactivation/removal step.

The log

10

of the ratio between these loads is the reduc-

tion factor. Each increment of 1 corresponds to a 10-fold

reduction in load. Thus, a log

10

reduction factor of 5 means

that the number of viruses remaining after the process has

been reduced 100,000-fold (10

5

-fold).

The virus reduction capacity of the two dedicated virus re-

duction steps pasteurization (in aqueous solution at 60ºC

for 10 hours) and virus filtration (nanofiltration) as well as

the HIC step was evaluated in a series of

in vitro

spiking

experiments. The mean overall virus reduction ranged from

≥

14.5 to

≥

19.9 log

10

as shown in Table 18. These validati-

on data for Berinert

®

show that pasteurization as well as

HIC and virus filtration (nanofiltration) effectively remove

a broad spectrum of viruses. This underscores the high

margin of safety of Berinert

®

in regard to the transmission

of viruses.

Virus

Manufacturing Stage

Virus Load of Spiked

Starting Material (log

10

)

Virus Load of

Final Sample (log

10

)

Virus Reduction

Factor (log

10

)

Overall Virus Reduction

Factor (log

10

)

HIV

Pasteurization

HIC

20N/15N virus filtration

6.1

8.5

7.6

≤

-0.5

≤

4.0

≤

2.5

≥

6.6

≥

4.5

≥

5.1

≥

16.2

BVDV

Pasteurization

HIC

20N/15N virus filtration

7.7

6.5

6.8

≤

-1.5

≤

1.8

≤

1.5

≥

9.2

≥

4.7

≥

5.3

≥

19.2

PRV

Pasteurization

HIC

20N/15N virus filtration

6.9

8.3

8.6

0.6

≤

1.8

≤

1.5

6.3

≥

6.5

≥

7.1

≥

19.9

WNV

Pasteurization

20N/15N virus filtration

7.5

9.5

≤

0.5

≤

1.5

≥

7.0

≥

8.0

≥

15.0

HAV

Pasteurization

HIC

20N/15N virus filtration

5.9

6.6

6.8

≤

-0.5

3.8

≤

1.5

≥

6.4

2.8

≥

5.3

≥

14.5

B19V

Pasteurization

5.4

1.5

3.9

NA

CPV

Pasteurization

HIC

20N/15N virus filtration

7.1

8.5

8.7

5.7

2.1

≤

1.5

1.4

6.4

≥

7.2

≥

15.0

HIV=

Human immunodeficiency virus

; BVDV=

Bovine viral diarrhea virus;

PRV=

Pseudorabies virus;

WNV=

West nile virus;

HAV=

Hepatitis A virus;

B19V=

Parvovirus B19;

CPV=

Canine parvovirus;

HIC=Hydrophobic interaction chromatography; NA=not applicable

Table 18 – Virus Reduction Capacity of the Manufacturing Process of Berinert

® 112