60

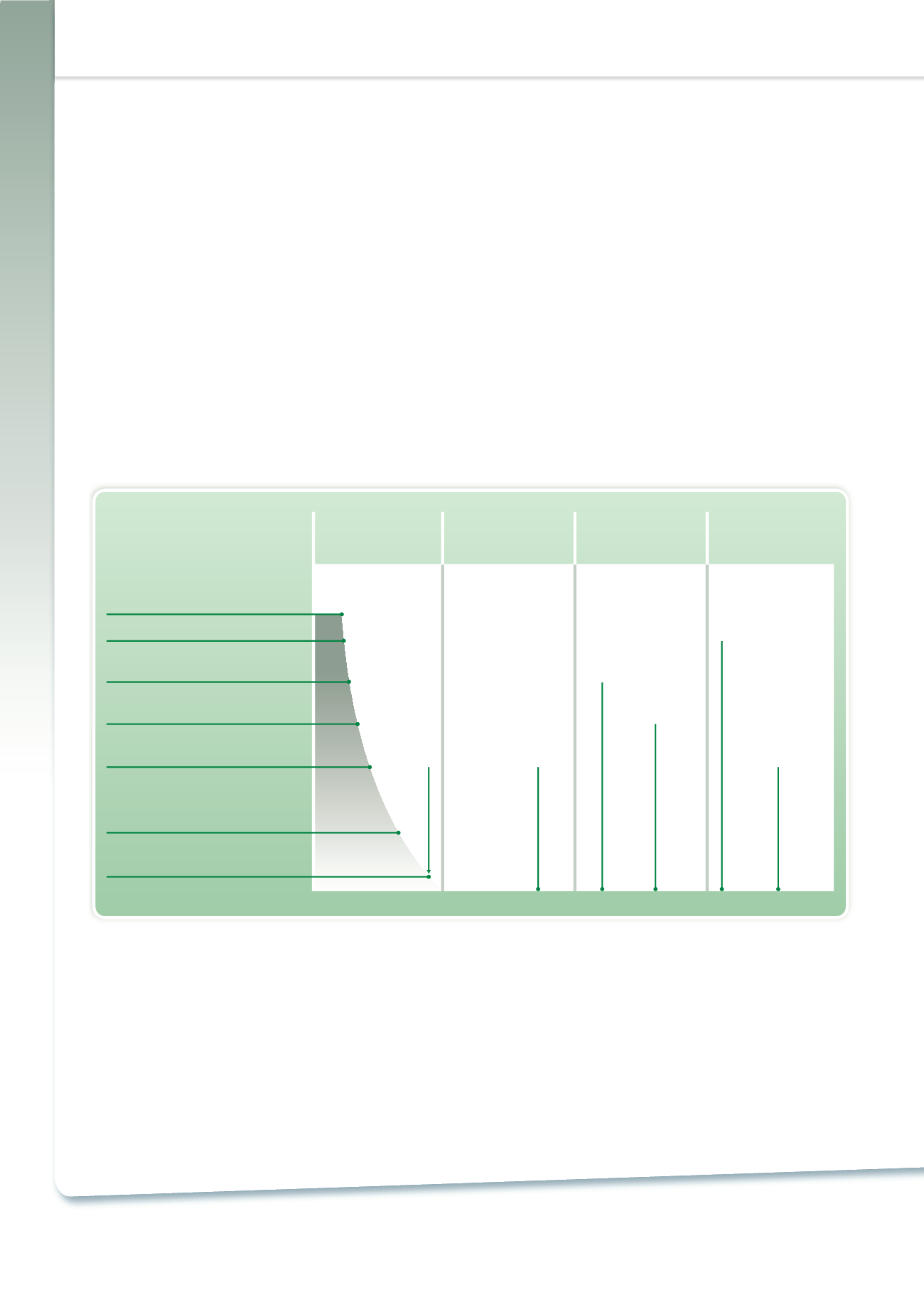

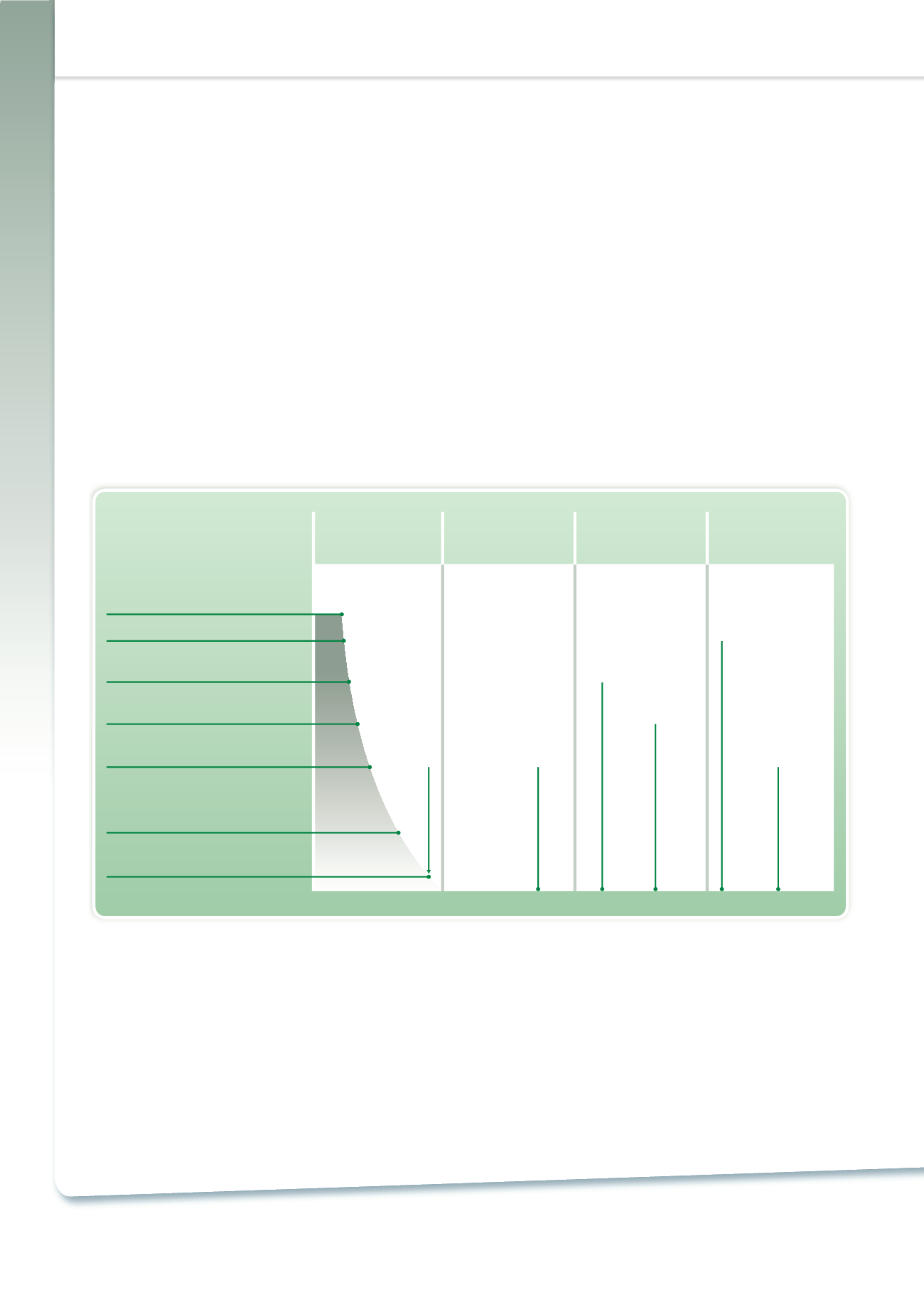

8.2 CSL Behring’s 4-Step Integrated Safety System

The safety of plasma products has reached a high level as

a result of the introduction of innovative technologies for

the inactivation and removal of viruses and prions. Based

on current understanding, the commercially available

plasma factor and inhibitor concentrates pose minimal

risk, and there remains only a theoretical risk of trans-

mission of infectious diseases.

As shown in Figure 31, CSL Behring employs a 4-step

Integrated Safety System to help ensure the quality of its

plasma protein products, including:

•

Careful donor selection and rigorous screening

of donations

•

Advanced manufacturing processes

•

Implementation of thorough Quality Control

and Assurance

•

Monitoring of the commercial products.

Selection of donation centers

1.

Plasma Selection and

Donation Control

2.

Manufacturing

Processes

3.

Quality Control

4.

Monitoring of

Commercial Products

Exclusion of donors who pose risk

Medical investigation of donors

Serological testing of donations

NAT/PCR testing of donations

Removal and

inactivation of potential

contamination present

Reporting and

evaluation of adverse

drug reactions and

performance of

appropriate measures

Documentation

of use

Internal quality control

Official certificate

and batch release

Inventory hold of source plasma with

lookback procedure

Computer monitoring of plasma

selection

Reduction

of potential

contamination

Release of plasma pools for fractionation

Figure 31 – CSL Behring’s Integrated Safety System for Plasma Derivatives

From Donation to the Finished Commercial Product

NAT=Nucleic acid amplification technology; PCR=Polymerase chain reaction.